Please give us your feedback

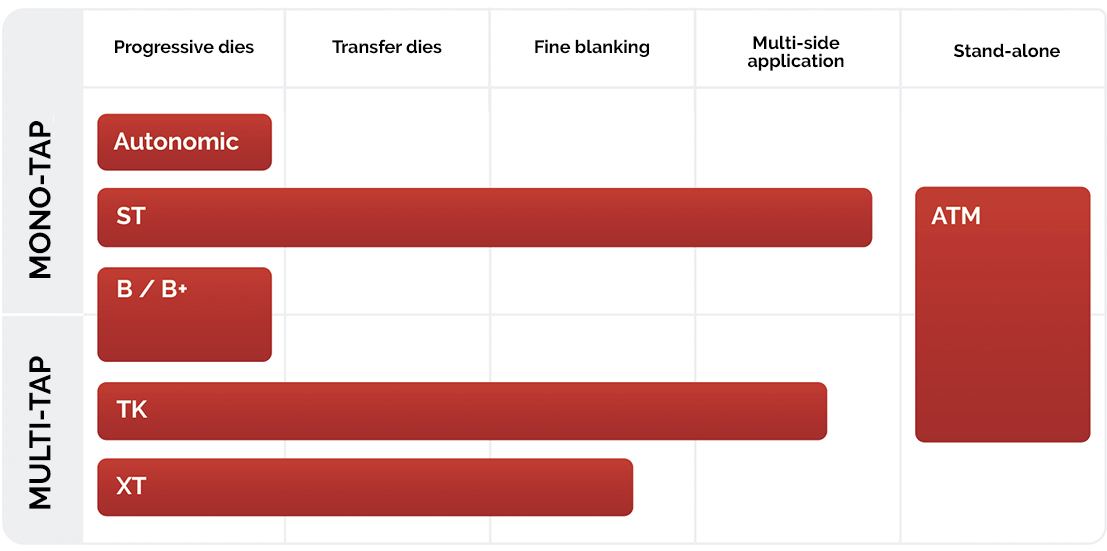

World leader of in-die tapping, we have a solution for you, whatever your technical constraints :

Tapping direction

Tapping direction

Output rate

Output rate

Center-distance

Center-distance

Fast approach

Fast approach

Clamping

Clamping

Piloting

Piloting

Strip following

Strip following

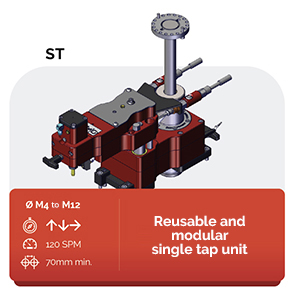

Fully reusable and easy to integrate, this newly design product line integrates the functionality of the complete tapping station.

The ST line includes different tapping unit models, with a version that integrates the strip following function (up to 45mm), thereby simplifying the die design and set-up of the tool. With their modular design, the ST units are easily reused and can be used to increase the flexibility for multi-tap applications or moved easily from one die to another.

Not only do you accelerate your ROI, but you also secure your production.

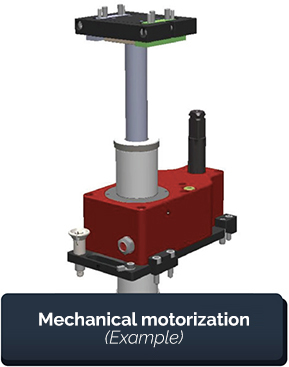

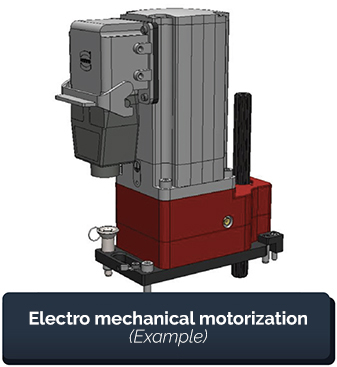

Available in Mechanical and Servo-motor versions.

Tapping capacity from M3x0.5 to M12x1.75 in standards DIN, ANSI or JIS; other dimensions possible.

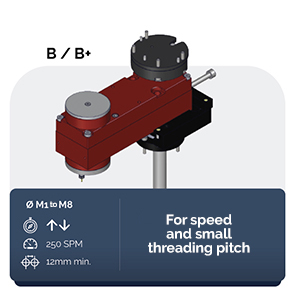

Particularly compact tapping units dedicated to single-tap applications at very high output rates.

Particularly at ease with high speed stamping applications (up to 200 strokes/min) and/or with small taps (S0.8x0.2mm for example), these units are based on our patented planetary gear technology to obtain such performances.

Available in Mechanical version.

Tapping capacity from M1.7x0.35 to M6x1.00 in standards DIN, AINSI or JIS; other dimensions possible.

The line of compact multi-tap tapping units that can do everything.

Whether the part is fitted with vertical, horizontal or inclined taps, small center-distance, different tapping diameters and many other particularities, this custom-made tapping unit will be able to meet your needs in the best possible conditions.

The TK units integrate perfectly into your environment, whether the part is produced in a progressive die, a transfer die or others.

Available in Mechanical and Servo-motor versions.

Tapping capacity from M3x0.5 to M12x1.75 in standards DIN, ANSI or JIS; other dimensions possible.

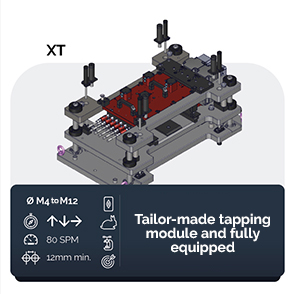

The ultimate Tapping Station module built by the specialist.

Even more refined than the TK range, these modules simplify the set-up of the tapping station when clamping, piloting, strip guiding and tapping functions are particularly overlapping. You will obtain, beyond unique responsiveness, the most adapted solution in terms of performance and compactness.

On the quality side, each module includes a systematic control of the tap presence which stops the press at the first defect and avoids production of poor-quality parts.

Available in Mechanical and Servo-motor versions Tapping capacity from M1.7x0.35 to M12x1.75 in standards DIN, ANSI or JIS; other dimensions possible.

The key element of any servo-driven tapping solution, the M400 is a modular and upgradable product capable of piloting of up to 4 motors. With a modern and ergonomic interface, it can control, beyond tapping, the collection of movements and sensors necessary for the solution to succeed and to simplify connections to the press.

The trolley will allow you to stock and move the control unit, lubrication system, cables, tapping heads, etc... in total comfort.

Producing and delivering defect-free parts is an absolute necessity today. To take on this challenge, PRONIC has developed a product called DETEC.

Installed on the other end of each tapped hole, it verifies the limit of tap travel and sends a signal to the press or the M400 tapping control mechanism: if this signal is NOK then the press stops.

To guarantee the longest possible tap life, outside oil quality, the most important factor is the means of delivery of the lubricant to the tap. Among the different techniques available, PRONIC has chosen a solution by micro-lubrication that, as well as guaranteeing the longest life possible, limits oil consumption, thereby lowering the price per part.

For certain applications (reinforced collets, for example), lubrication through the center of the tap gives the best performances and leads to parts being kept very clean, thus avoiding in certain cases the washing operation.

With or without flutes, prepared for lubrication through the center or not, the taps sold by PRONIC are developed by the German company BASS GmbH. Strengthened by more than 10 years of cooperation, we are capable of bringing you the strongest taps for the toughest application.