Please give us your feedback

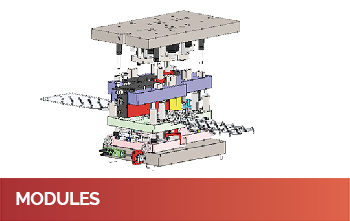

The insertion heads are installed either solid on the lower shoe (limiting the potential shocks) or mobile in the upper part of the tool: the client and/or the constraints of the part decide on this. The integration of the insertion heads in the tool is very simple: installation is done in just a few minutes thanks to the use of mounting systems and rapid industrial connectors for all types of feed (electrical, pneumatic and inserts); in addition, thanks to a dedicated poke-yoke system, set-up errors are avoided.

A kart, connected to the die, feeds the insertion heads via a distribution system best adapted to the part (vibrating bowl, etc.); this kart, equipped with 1 to 3 distribution systems can feed up to 4 heads via specific, flexible feeder pipes.

Several component references and dimensions can be inserted simultaneously in series up to 60 (or more) parts per minute per head (depending on the application and die parameters).

Generally independent from the die kinematics, each head can be used in several applications, offering investment optimization and/or securing the means of production.

PRONIC can also supply a complete range of punches dedicated to the insertion operations.

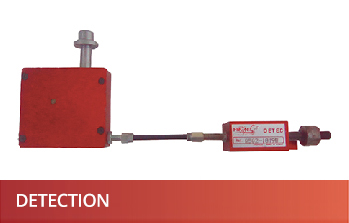

Finally, the PRONIC Detec system guarantees 100% accurate parts, i.e. the presence of the insert in its correct position.

PRONIC guides you throughout the project and in particular to sign off the integration of the insertion head into your die design.

Insertion type : Deformation insert

Frequency : 30 cps/min

Insertion direction : ![]()

Transfer of the Trolley head : air pressure

Watch the video

Find out more

More videos

Insertion type : Band deformation

Frequency : 30 cps/min

Insertion direction : ![]()

![]()

Dimensions : M4 à M10 et plus

M4 to M10 and more

Insertion of standard nuts available on the market or specific nuts

Transfer of the trolley head : air pressure or intubation

Watch the video

Find out more

More videos

Insertion type : Deformation insert

Frequency : Up to 40 cps/min (within the parameters of the tool).

Insertion direction : ![]()

![]()

Insertion in 2 steps : insertion/pre-setting and final calibration.

Insertion from top to bottom with the mounting beneath the mobile support, or from top to bottom with the head mounted on the upper part of the tool, the heads being reusable.

Customizable and adaptable to, in respect of its surroundings and the fragility of the functional parts of the articulations of the head.

Transfer of the trolley head : air pressure and gravity

Watch the video

Find out more

More videos

Insertion type : Deformation insert

Frequency : 30 cps/min

Insertion direction : ![]()

![]()

Transfer of the trolley head : air pressure or intubation

Watch the video

Find out more

More videos

Insertion type : Deformation insert

Frequency : up to 50 cps/min (within the parameters of the tool) and up to four bushings at a time

Insertion direction : ![]()

![]()

Dimensions : insertion of the bushings from ø9 to ø25mm (others upon request), thickness 0,5- or 1-mm. Insertion from bottom to the top (preferred) with the head mounted on the lower plate, or from the top towards the bottom with the head mounted on the upper part of the tool heads reusable. Insertion in 3 or 4 steps depending on the type of bushings.

Complete solution with the distribution trolley mono or bi or multiple outlets + flexible distribution conduits, markings + detection + control.

Transfer of the trolley head : air pressure

Watch the video

Find out more

More videos

Insertion type : Deformation insert

Frequency : 25 to 40 cps/min

Insertion direction : ![]()

![]()

![]()

Transfer of the trolley head : air pressure or intubation

Watch the video

Find out more

More videos

Insertion type : Deformation insert

Frequency : 40 to 50 cps/min Autonomous head of the press

Insertion direction : ![]()

![]()

Transfer of the trolley head : air pressure

Watch the video

Find out more

More videos

Insertion type : Deformation insert

Frequency : 30 to 40 cps/min

Insertion of all types of studs.

Insertion from top to bottom uniquely, re-usable heads.

Insertion direction : ![]()

Transfer of the trolley head : air pressure

Watch the video

Find out more

More videos

Insertion of special.

Insertion bottom-up or top-down (e.g. up to 4 spacers per press stroke), reusable heads.

Insertion 1 step (e.g, bearing in a pre-formed collet) or 2 steps.

Tailor made and adaptable to the environment.

Complete solution with distribution kart (up to 3 bowl feeders) + flexible feeder pipes + detection and control.

Rate : up to 40 strokes/min (depending on the type of inserts and die parameters).

Transfer of the trolley head : air pressure or intubation

More videos

FEATURES :

• Quick connections

• Quick assembly kit

• Reusable in multiple tools

• Insertion possible in all directions: up, down, sideways

FEATURES :

• 1 to 3 vibrating bowls

• 2 to 6 outputs

• Quick connections

• Easy to move

Pronic can offer a complete customized solution (machine module); the only thing left to do is to install the tool in the space reserved for it.

Reliable mechanical system based on our expertise in tapping under pressure assuring the fabrication of good pieces.

Flexible conduits adapted to insertion (form, masse, etc.) and its kinematics.

Poinçons (for bushings): made for measure