Please give us your feedback

For electrical wire clamping components

• Parts fed from a reel, in line with the customer's press;

• Servo feed system;

• 6 servo-motorized tapping heads with torque monitoring per tap;

• Cutting of components at the end of the process, with integrated damping solution;

• Automatic removal of NOK parts without stopping the machine;

• Traceability guaranteed thanks to a finished parts collection system;

• No machine downtime for changing customer trays

• Ergonomic interface with color touch screen.

For tapping cast metal parts

• Parts fed via hopper;

• Automated loading using a vibrating table equipped with a camera and robot;

• 10-station rotary table, horizontal and vertical tapping;

• Tapping stations on XY table;

• Multi-station unloading into customer bins.

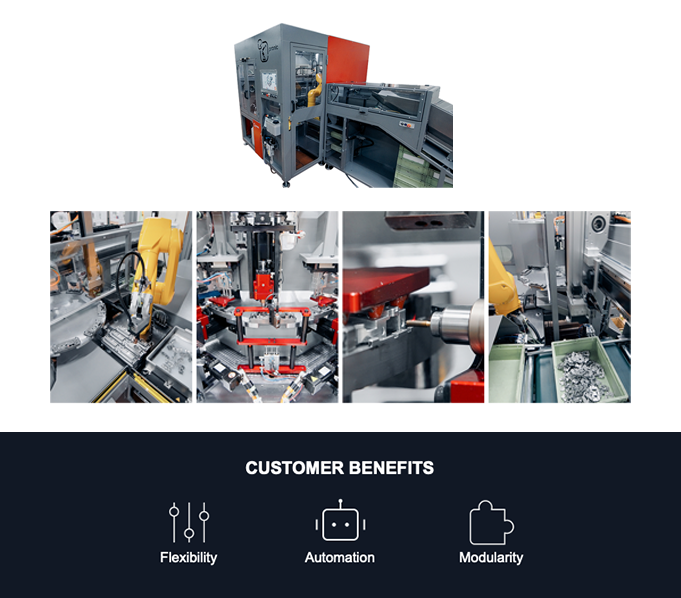

WHY CHOOSE PRONIC ? Pronic is the expert in In-Die solutions for tapping and inserting stamped parts. Specific constraints (material, part complexity, production rates, etc.) require our customers to produce their parts on dedicated equipment out of the press.

Our areas of expertise:

• Machines inline with presses or offline,

• Robotic cells requiring flexibility and modularity.

With over 30 years of expertise, we support our customers worldwide in designing customized tapping and insertion solutions that meet your needs and enable you to reduce costs, increase rates, and gain flexibility.