Please give us your feedback

Pronic can supply tapping and fastener solutions that fit into your existing press equipment.

Sometimes you are no longer satisfied with your In-Die solution, whether it was developed in-house or purchased from a supplier.

Pronic has the ability to incorporate its insertion or tapping systems into an existing environment and limit integration costs.

Ask for a quote

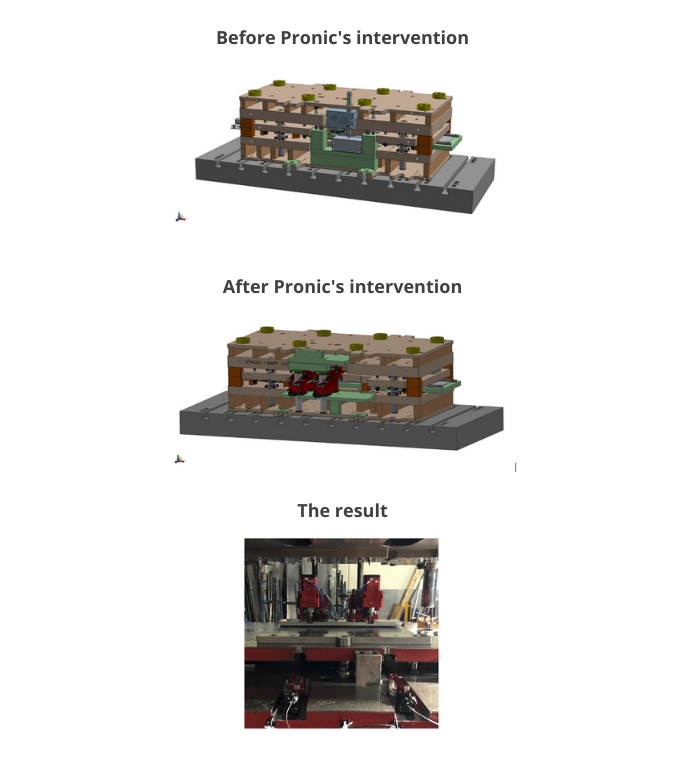

Example of an In-Die tapping solution

The requirement: Our customer wanted to replace its In-Die tapping system, which was limited to 19 spm.

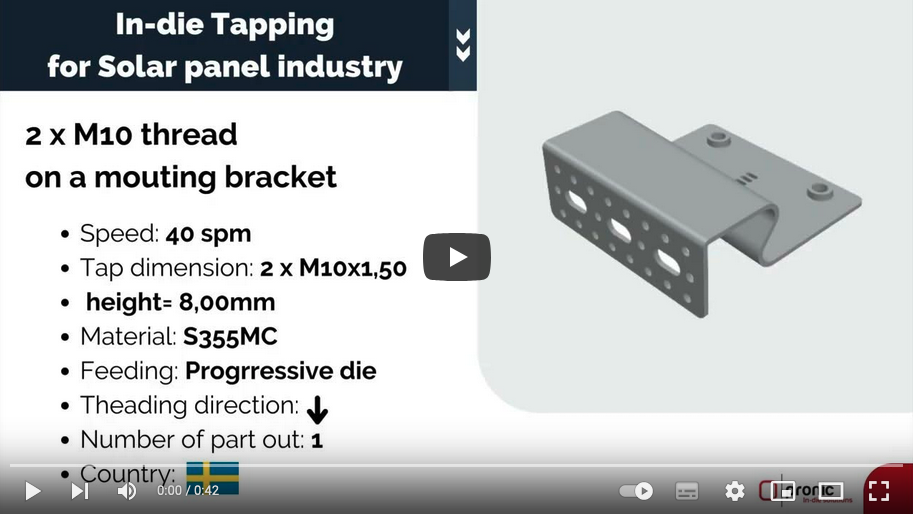

The application concerns a mounting bracket for photovoltaic panels with 2 x M10x1,50 on a height of 8mm.

The project constraint: keep the tool modification to a minimum

The Pronic solution:

- Conservation of kinematics and location in the tool

- Design of a new tapping station with the integration of 2 single-tap units from the ST range

- Start-up and optimization of the production on site.

The result:

A production tool, reliable and efficient with a production rate doubled and fulfilling the customer's expectations at 40 strokes/min.

Customer Testimonial

I found out about PRONIC through word of mouth. We needed in-die-tapping solutions for our business so I decided to call on Pronic. For me, the objective was to gain in efficiency. In the end, I am really satisfied with Pronic's services: from the definition of the project, then support through to implementation and training. I highly recommend them! I will end with a quote from Robert Frost: "The world is full of good people. Some want to work and others want to let them." We decided to let Pronic do it.

Sekelj Tomas, Design Engineer - Tooling Department, Nitator Hylte AB in Sweden

Special thanks to our Swedish distributor A-Tooling - Anders Nyberg

Not satisfied with your existing In-Die tapping or insertion solution?

Call on Pronic's expertise!

Our team will work with you to find the best solution for optimal performance.

Contact us