Please give us your feedback

Safety and comfort for drivers For safety, the use of high-strength steel ensures that seats and seat mountings can withstand the stresses of accidental impact. For comfort and technology, a wide range of adjustment options and the addition of motorizations enable customers to achieve ever-higher levels of comfort.

Why use guide bushings? With the multiplication of adjustments, more parts are in motion, requiring guidance and articulated solutions. Seat manufacturers are therefore turning to deformable guide bushings. These guide bushings are used to reduce friction and noise in the articulated components of automotive seats. They are an ideal replacement for bearings, which are more expensive, bulkier and heavier.

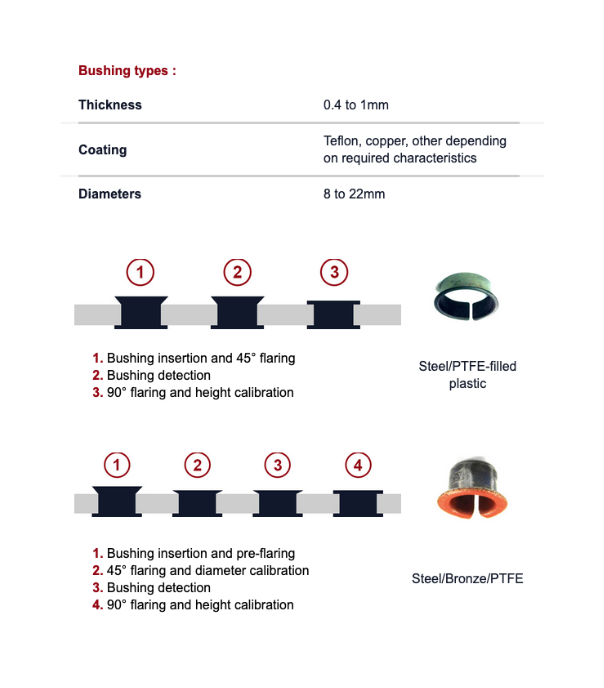

How do guide bushings work? Guide bushings are metal strips with a coiled anti-friction coating. They provide precise, economical guidance in just a few steps:

- Installation in the housing

- Deformation on itself to obtain a calibrated diameter and precise height.

INSERTING THESE RINGS UNDER PRESS ALLOWS YOU TO OBTAIN - Increased productivity

- Lower logistical costs (as parts leave the machine finished, without the need for additional operations).

- Automatic control of insertion, guaranteeing optimum quality

Find out more about In-Die insertion

Partnerships with industry players Since 2011, we have been working with leading automotive seat manufacturers such as :

![]()

Our In-Die bushing insertion equipment is in operation in Europe, North America and Asia.

![]()

• Stamping site • PRONIC

The advantages of our equipment Using our range allows you to:

- Insert fasteners top-down, bottom-up or sideways

- Share insertion systems between several tools

- Low integration costs

- Quick implementation thanks to assembly kits and quick connections

- 100% part insertion guaranteed thanks to our patented detection system

Request your quote online

Application examples Click on the thumbnails below to view some examples of In-Die bushing insertion applications:

- Tapping and Bushing insertion

- In-Die Insertion system for Ø14 and Ø10 bushing

- In-die Bushing insertion by Pronic

Whether your project involves tapping, insertion in the die or off press (machine, robotic cell), don't hesitate to contact us. Our team is ready to help you!

Contact us