Laissez-nous votre avis

Système d’insertion sous presse complet sur mesure qui répond à vos exigences et bien plus encore

TOUS LES PRODUITS PRONIC

POUR L'INSERTION SOUS PRESSE

SONT CONÇUS ET RÉALISÉS

SUR MESURE

Fort de son expérience dans le taraudage sous presse, PRONIC a développé un système complet d’insertion sur-mesure.

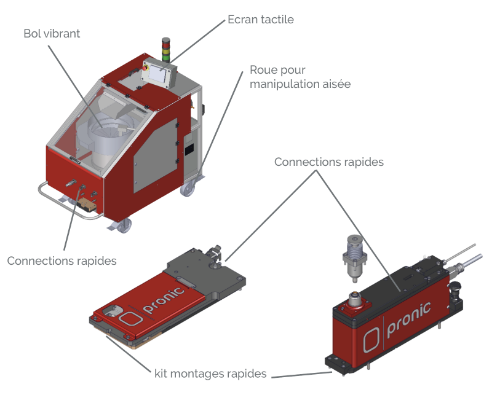

Un chariot de distribution connecté à la presse alimente les têtes d’insertion avec un bol vibrant et des gaines de soufflage flexibles ou des gaines de gavage.

Les têtes d’insertion sont installées au-dessus ou au-dessous de la bande en fonction de la meilleure cinématique de sertissage.Indépendant de la cinématique de l’outil, chaque tête peut être utilisée dans plusieurs outils.

L’installation se fait en quelques minutes avec l’utilisation du kit d’installation rapide et de connections rapides pour toutes les alimentations (électrique, pneumatique et bagues).

Plusieurs références et dimensions de composants peuvent être insérées simultanément à cadence jusqu’à 60 pièces par minute par tête.

PRONIC garanti 100% de pièces insérées grâce à de nombreux capteurs présents dans le chariot et les têtes d’insertion.

AVANTAGES :

Connexions rapides et industrielles :

conception adaptée à l’environnement des presses.

Réduction des investissements :

Réutilisation des têtes de mêmes composants dans plusieurs outils.

Sécurité de fonctionnement :

tête et chariot sont sécurisés par de nombreux capteurs avant insertion.

Kit d’installation rapide :

installation simple, rapide, sans outil spécifique.

CHARIOT

TÊTES

Nos équipements sont constitués d’un système de distribution des composants et d’une ou plusieurs têtes qui procèdent à l’insertion de ce composant dans l’outil et à sa mise en place.

CARACTÉRISTIQUES :

POINTS FORTS :

Pronic a déjà réalisé une grande variété d’applications pour l’insertion de divers types de composants aux caractéristiques différentes.

CARACTÉRISTIQUES :

POINTS FORTS :

TÉLÉCHARGER CES FICHES INSERTION EN PDF

DÉCOUVRIR CES SOLUTIONS D’INSERTION SOUS PRESSE EN VIDÉO

DEMANDER UN DEVIS EN LIGNE

DEMANDE DE DEVIS